Namhlanje, masiququzelele indlela ecwangcisiweyo yokhuseleko lokusebenza komatshini wokungakhathali. Ngelixa sele sinokuqonda ngokubanzi malunga nokusebenzisa iividiyo zokufundisa, kubalulekile ukuba zilungiselele umkhondo wemveliso i-velojinic yomatshini wokuphambuka kunye nokuqinisekisa ukusetyenziswa kwayo, kufuneka siziqhelanise ne Isikhokelo sezokhuseleko sokusebenza umatshini. Oku kuya kusenza sikwazi ukwenza kakuhle umsebenzi wokunciphisa umda.

- Njengembali yomatshini wokungagungqisisisa, ukuhanjiswa kwe-nitrogen ye-witrogen kubalulekile. Ngaphambi kokuqala, qala uvule i-nitrogen ye-nitrogen ye-nitrogen. Nceda uqaphele ukuba uxinzelelo lobonelelo nge-nitrogen yolwelo kufuneka ibe phakathi kwe-0.5 ~ 0.7MPA. Uxinzelelo oluphezulu lokubonelela nge-nitrogen ye-nitrogen iya konakalisa i-nitrogen ye-nitrogen ye-nitrogen.

- Jikelezisa i-swinca yencwadana yemigaqo kwi-Swings] isikhundla [sencwadana].

- Cinezela iqhosha lokuqalisa kweMisebenzi yokuSebenza, ngeli xesha uKukhanyisela inkathalo yombane iya kukhanyisa.

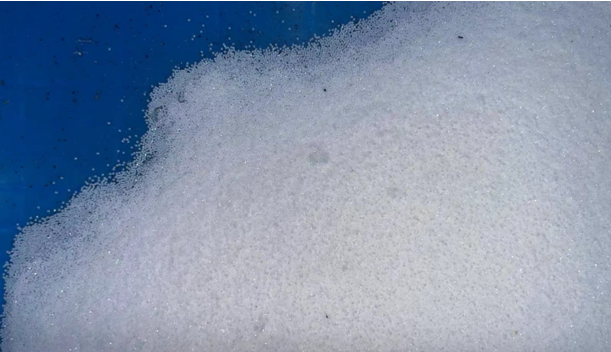

- Vula umnyango wegumbi lokusebenza, kwaye emva kokubeka ii-pellets ezomileyo kwizixhobo, vala ucango. Cinezela iqhosha le-ejector ukuqala ukujikeleza kwevili le-ejector, kwaye ulungelelanise i-ejeccy ye-ejector ye-ofisi ye-Eject Heeli.

- Cinezela iqhosha le-scbram yokuqalisa ukusebenza kwesikrini sokugcwalisa. Xa isikrini esijikelezayo sisebenza, iipellets ziya kusasazwa kwaye zidutyulwe kubushushu begumbi.

- Gcina le meko ingentla kwaye uqhubeke nokusebenza kwemizuzu engama-45. Qinisekisa ukusasazwa okuqhelekileyo kweepellets ngokujonga umngxunya wokujonga kwicandelo le-Pellet kunye nesandi se-pellets ukubetha umatshini. Emva kokugqitywa kokusebenza, cofa iqhosha lokuhambahamba kwi-scract screen ukumisa isikrini sokuhambahamba ngaphambi kokuba ucinezele iqhosha le-ejector hit ukumisa ukujikeleza kwevili le-ejector.

- Xa ukukhanya kwesalathisi ukukhanya kukhanya, nceda ulumkele ukuba unganikina isandla sakho xa uvula okanye uvala umnyango wegumbi lokusebenza. Qinisekisa ukuba ucango lwegumbi lokusebenza luvaliwe. Qiniseka ukuba uyeke isikrini esijikelezayo ngaphambi kokumisa ivili le-ejector.

Phawula:Ukuba i-pellets igcinwe kwicandelo le-Pellet, kunokubakho ingxaki ngothutho olugudileyo lweepelethi xa kucinyiwe izixhobo. Ukuqinisekisa ukuba izixhobo ziyakwazi ukufumanisa ngokukhawuleza amagunya e-culting xa esebenza kwakhona, nceda ugcine iipellets ezigcinwe kwiscreen esijikelezayo xa izixhobo zikwisimo esimiselweyo.

Indlela yokuphendula:Misa isikrini esijikelezayo ngaphambi kokumisa ivili le-ejector. Guqula ukutshintshela kwencwadana yemigaqo kwizikhundla ezizenzekelayo.

Xa useta umlawuli wamaqondo obushushu kunye nexesha lokuphela kwamafutha, kufuneka ukuba kuqwalasele ubushushu bemveliso ngelo xesha kwaye wongeze ixesha elifanelekileyo le-2 ukuya kwezi-3.Umlawuli wesantya esinamavili we-2 ukuya kwi-COSTARY REATLER. iimeko zokwenza izinto eziyimfuneko kwiimveliso zenziwe

I-POPTAL: I-NoV-07-2023